Full Counterweight LS Crankshafts: Block Clearancing Guide + Spool 4.000" Billet LS Crank

Full Counterweight LS Crankshafts: Why They’re Better — and the Block Clearancing You’ll Need

Chasing reliability in a serious LS build? A full counterweight (CCW) crankshaft is one of the most effective upgrades for stability, bearing life and smoothness across the rev range. Spool Imports now offers a 4.000" billet full counterweight LS crankshaft engineered for boosted and high-RPM combinations.

There’s one crucial catch many builders miss: a CCW crank won’t clear an OEM LS block without machining. This article explains why CCW matters, where interference happens, and how to clearance the block properly.

Contents

- Why full counterweight (CCW) cranks exist

- Fitment reality in OEM LS blocks

- Where the interference occurs

- Clearancing procedure (step-by-step)

- Spool 4.000" Billet CCW LS Crank — key specs

- FAQ

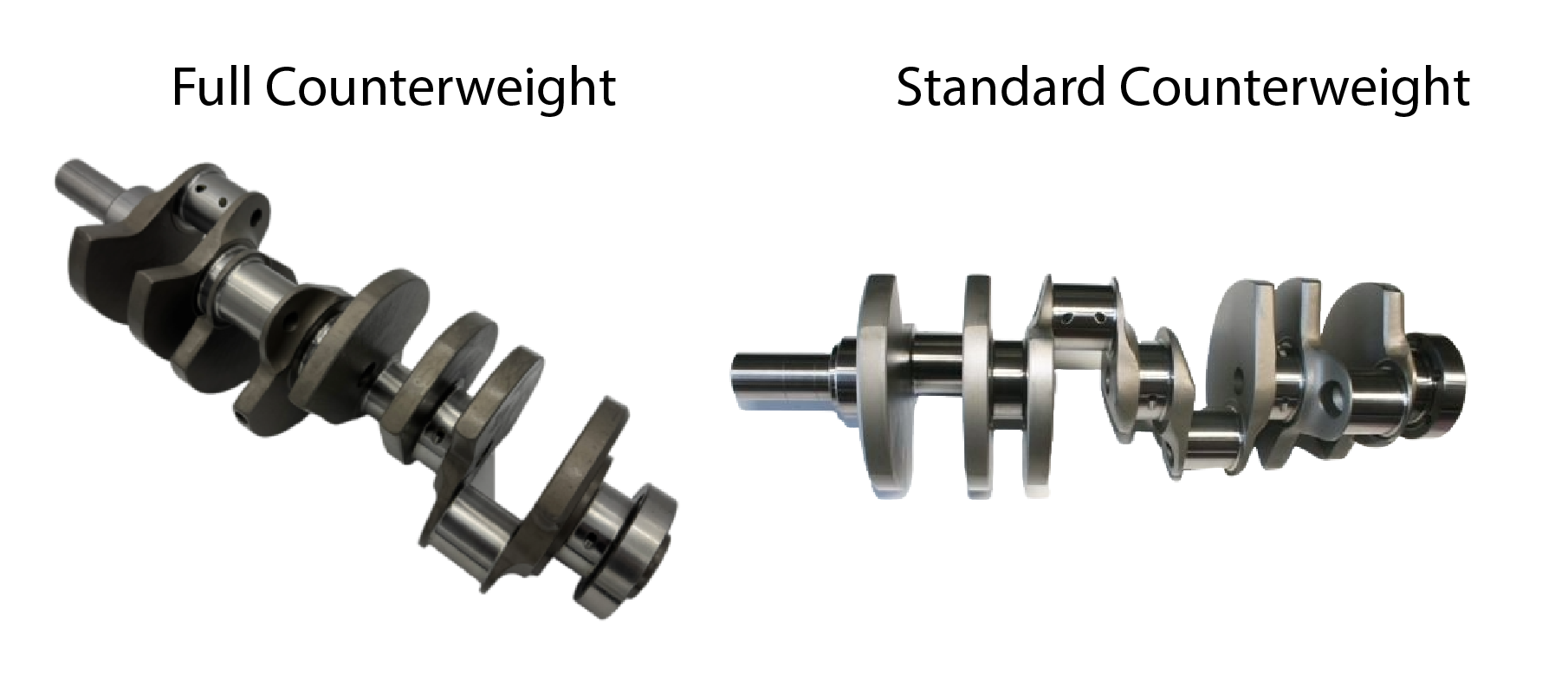

1) Why full counterweight (CCW) cranks exist

Most OEM and many aftermarket LS cranks are not fully counterweighted through the centre mains. That’s fine at factory power, but when you add RPM and cylinder pressure, the missing opposing counterweights mean more flex and uneven bearing loads.

- Higher rigidity: reduced crank flex across the centre mains

- Better balance & harmonics: smoother operation throughout the rev range

- Longer bearing life: more even load distribution

- Lower risk of vibration-related damage

2) Fitment reality in OEM LS blocks

Important: A full counterweight crank will foul on an unmodified OEM LS block. The extra counterweight mass near the centre mains needs additional clearance in the block’s webbing/thrust areas. This applies to both iron and aluminium OEM blocks.

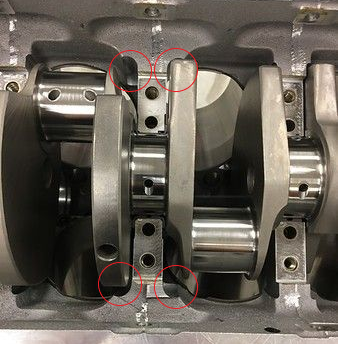

3) Where the interference occurs

The most common contact zones are:

- Centre main webbing (typically around mains #3–#4)

- Thrust main shoulders

- Localised casting ribs or thick sections near the internal bay windows

Typical OEM LS Block Interference Zones (Top View)

4) Clearancing procedure (step-by-step)

Tools & checks: Dummy bearings, machinist’s dye/marker, feeler gauges, die grinder with carbide burrs, blending rolls, deburring tools, and accurate measuring instruments. Work clean, re-measure often.

- Initial mock-up: Install the crank without bearings. Rotate slowly and mark any contact/scuff points on the block webbing and thrust areas.

- Relieve material conservatively: Remove small amounts around the marked zones, keeping shapes smooth and symmetrical. Preserve block rigidity.

- Measure clearance: Refit and rotate. Aim for ≥ 0.060" (≈ 1.5 mm) static clearance all around the counterweights.

- Blend & deburr: Radius transitions and remove burrs to reduce stress risers and improve oil return.

- Final verification: Mock up again with bearings torqued. Verify free rotation and confirm clearance at multiple crank positions.

Pro tip: The goal is adequate clearance with maximum retained material. Don’t “hog out” the webbing — work slowly, measure often, and keep everything symmetrical.

5) Spool 4.000" Billet CCW LS Crank — Key Specs

- Stroke: 4.000"

- Design: Full counterweight (centre counterweights included)

- Material: High-quality billet steel

- Use case: Boosted/high-RPM performance and race engines

- Pairing: Ideal with Spool H-Beam or Drag Pro I-Beam conrods (ARP L19 upgrade available)

Need help? Our tech team can advise on clearancing best practices and component pairing for your combo.

6) FAQ

Will a full counterweight crank fit a stock LS block without machining?

No. The centre counterweights will contact the OEM block webbing/thrust areas. Machining is required.

How much clearance should I allow?

Target ≥ 0.060" (≈ 1.5 mm) around the counterweights after final mock-up with bearings installed and caps torqued.

Iron vs aluminium blocks?

Both typically require clearancing. Approach is the same: remove minimal material, keep symmetry, verify often.

Will block clearancing weaken the block?

When done correctly (conservative removal, smooth blends, retained symmetry), the impact on rigidity is minimal while the benefits of a CCW crank are significant.

Ready to build it right the first time? Talk to Spool Imports about our 4.000" Billet Full Counterweight LS Crankshaft and matching rod/piston packages.