Why Getting Your Piston-to-Bore Clearance Right Matters – Especially with Forged Pistons

Why Getting Your Piston-to-Bore Clearance Right Matters – Especially with Forged Pistons

By Spool Imports

When you're building a performance engine, especially with forged pistons, one of the most critical things to get right is piston-to-bore clearance. Get it wrong, and you risk anything from excessive blow-by to a full-on engine failure. Get it right, and you’ve got a solid foundation for serious power.

What Is Piston-to-Bore Clearance?

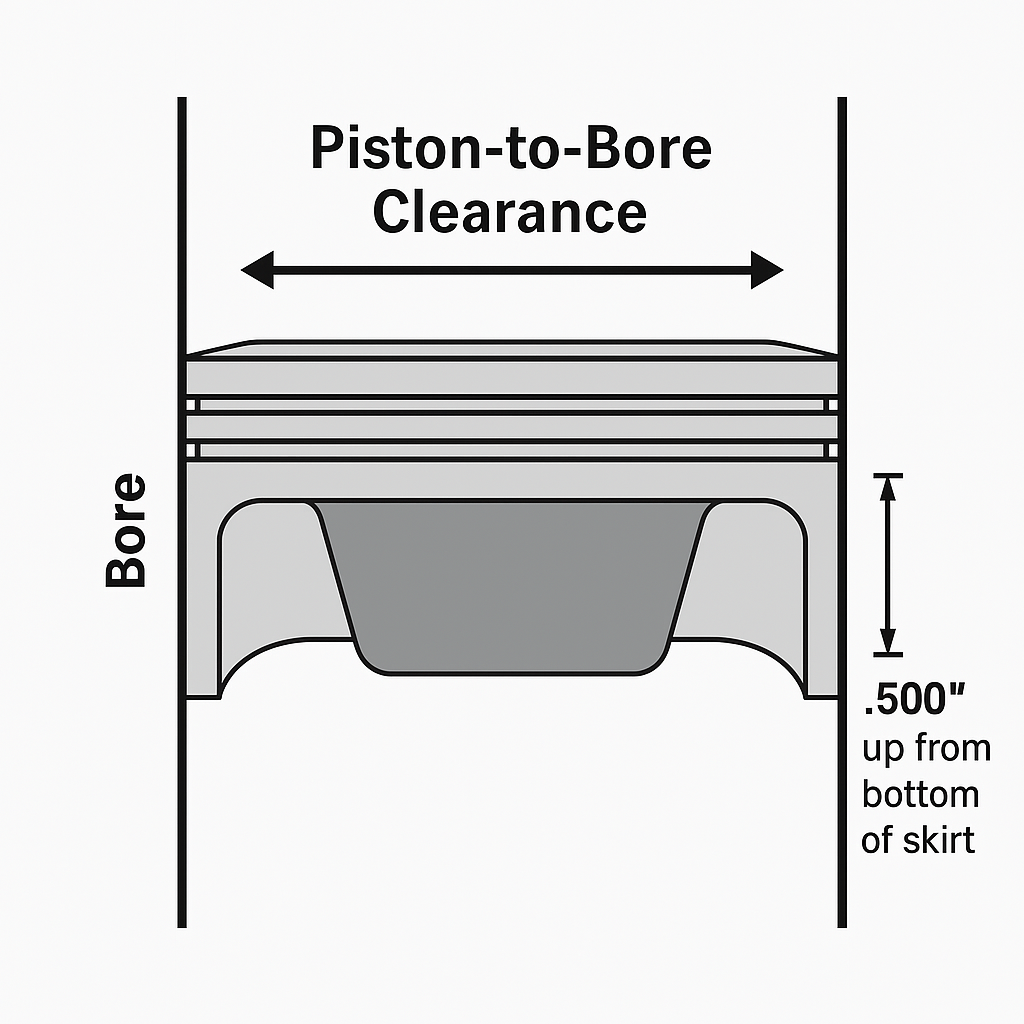

Piston-to-bore clearance is the measured gap between the outside of your piston and the inside of your cylinder bore. It’s usually measured at the bottom of the piston skirt, perpendicular to the gudgeon pin, and it’s expressed in thousandths of a millimetre.

It might seem like a tiny detail, but this little gap plays a huge role in how your engine performs – and how long it lasts.

Forged Pistons Expand More Than Cast

Here's the big difference: forged pistons expand more when they heat up. That means they need more clearance than cast pistons when cold to allow room for expansion once they’re at operating temp.

If you don’t allow enough clearance, the piston can scuff against the bore – and trust us, that’s not the kind of "performance" you're looking for. We’re talking serious damage: skirt scuffing, oiling issues, or even a seized engine.

On the flip side, too much clearance can lead to piston slap (that loud ticking noise on cold start), poor ring seal, and oil consumption.

There’s No One-Size-Fits-All Spec

The right clearance depends on the piston design, the intended use, the fuel you're running, and even the engine’s bore size.

At Spool Imports, we work with top brands like CP Carrillo and Ross Racing Pistons – and we always recommend following their spec sheets for clearances. They know how their pistons behave under heat and load, and they’ll give you a range depending on whether you're building a street car, a high-revving N/A engine, or a high-boost turbo monster.

For example:

- A Barra turbo street build with CP Bullet pistons might want around 0.0035" to 0.0045".

- A full-tilt drag build on methanol? You might be looking at 0.005"+.

How to Measure It Correctly

CP-Carrillo pistons usually come with a spec sheet that indicates the correct measurement point – often 0.500" up from the bottom of the skirt or as otherwise specified. This point is important because pistons are not a uniform diameter all over – the clearance must be measured where the manufacturer intended.

What If You Don’t Have an Off-the-Shelf Option?

That’s where custom pistons come in. We can get custom CP Pistons made to suit your exact clearance and compression ratio needs. Turnaround is usually 5–8 weeks, and it's the best way to tailor your build if you’re chasing big boost or dealing with an unusual combination.

We also stock our exclusive Barra Bullet pistons in different compression ratios – including 9:1, 10:1 and 12:1 – so you’ve got options right off the shelf.

Pro Tip: Always Measure and Hone

Don’t assume your bores are perfect. Measure them! And if you're fitting new pistons, always hone your block to match the pistons, not the other way around. Machining to the right clearance is key – that’s why we recommend working with a machinist experienced with performance builds and forged pistons.

The Bottom Line?

Setting the correct piston-to-bore clearance is critical. It’s the difference between a reliable 1,000hp street car and a blown-up garage ornament.

Need help choosing the right piston or clearance specs for your build? Give us a call or drop us a message – the team at Spool Imports is here to help.

We supply CP, Ross, and Spool-spec custom pistons for most popular performance engines. Shop online at spoolimports.com or get in touch for custom options.